Multi-ply fabric conveyor belts are advanced material handling solutions designed for heavy-duty industrial applications. These belts are constructed with multiple layers of fabric reinforcement, typically ranging from 2 to 8 plies, bonded together with high-quality rubber compounds. The innovative design combines strength, flexibility, and durability to meet the demanding requirements of modern industrial operations.

Construction

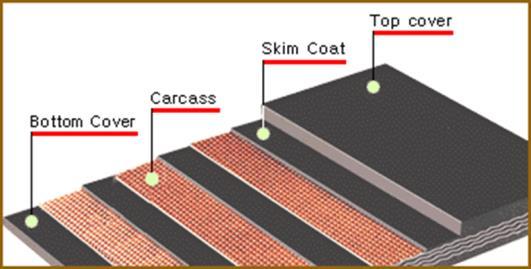

Multi-ply fabric conveyor belt consists of three parts:

Cover Rubber — top & bottom cover rubber,

Skim Coat — an extra layer compound between plies,

Carcass — one or more plies EP or NN fabrics.

It’s widely used in the fields of Mine, Ports, Electric Power Plant, Metallurgy, Cement Plant, etc.

Multi-ply conveyor belts are classified based on their reinforcement materials:

● Traditional construction with cotton fabric layers

● Moderate strength and flexibility

● Suitable for medium-duty applications

● Cost-effective solution for general conveying

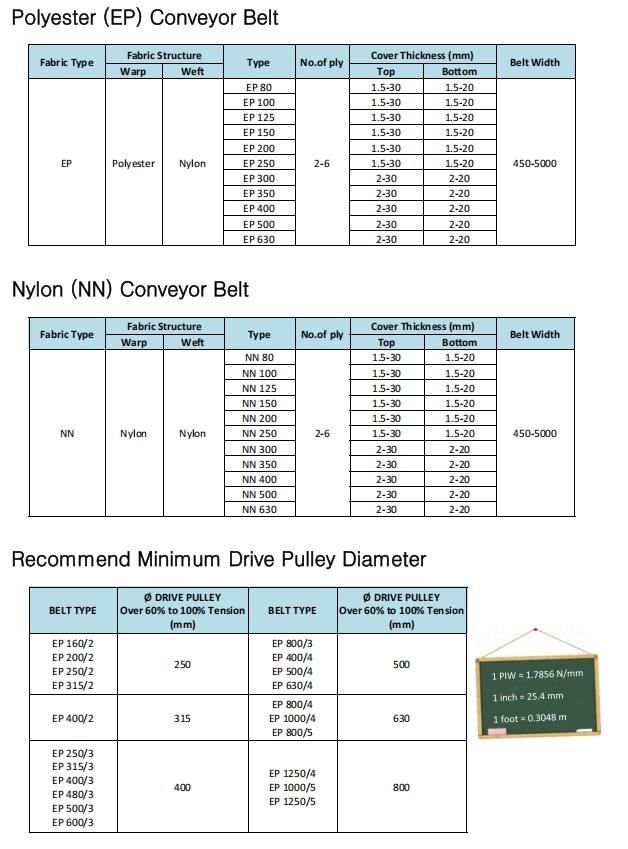

● Nylon fabric reinforcement in both warp and weft directions

● Excellent elasticity and impact resistance

● Good troughability and flexibility

● Low elongation properties

● Ideal for medium to long-distance conveying

● Polyester warp with nylon weft construction

● Highest tensile strength among fabric belts

● Minimal elongation under load

● Excellent heat resistance

● Suitable for heavy-duty, long-distance applications

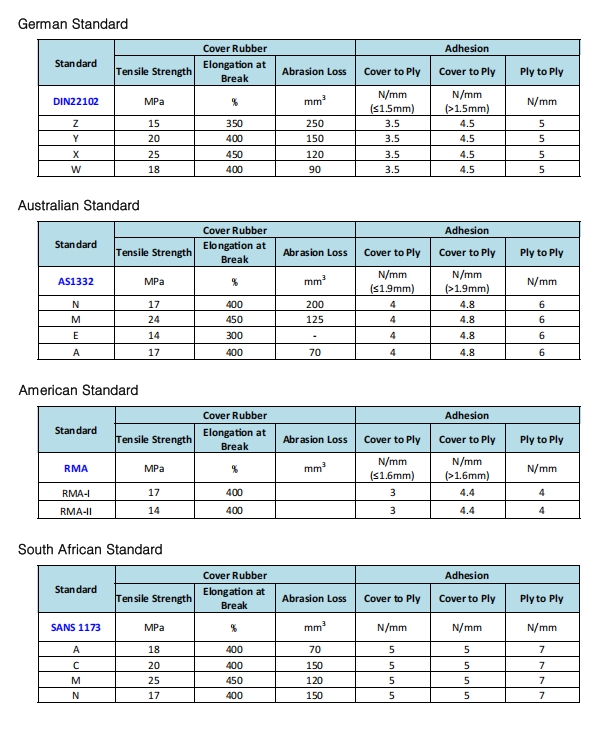

Standard of Cover Rubber

In accordance to international standards, such as DIN22102, RMA, AS 1332, SABS 1173/2000, JISK6322, etc.